Whitfield Operating Instructions (short

version)

Back to pellet stove repair

Back to main Whitfield Pellet Stove Page

Congratulations on the purchase of your Whitfield Pellet Stove!

When you purchased your Whitfield you joined other ranks of thousands of concerned

individuals who's answer to their home heating system reflected their concern for

aesthetics, efficiency, and our environment. We extend our continued support to help

you achieve the maximum benefit and enjoyment available from your pellet stove.

Please familiarize yourself with this Owner's Manual before installing your Whitfield

stove. This manual covers, in detail, the necessary steps required in assembling and

installing your Whifield Pellet stove in a safe manner.

We at Pyro Industries, Inc., the manufacturer of the "Original Pellet Stove" thank you

for selecting a Whitfield as the answer to your home heating needs.

Sincerely,

All of us at Pyro Industries, Inc.

PELLETS - IMPORTANT: PLEASE READ

GENERAL INFORMATION

The Whitfleld Advantage has been designed to burn wood residue pellets and non-wood pellets with up to

3% ash content (i.e... cardboard, nut hulls etc...). Agricultural pellets (i.e... corn, alfalfa etc..) are not

permitted to be burned in your stove. Dirty fuel will adversely affect the performance of the stove.

Caution: The use of dirty, wet and/or high sodium content fuel may void the warranty!

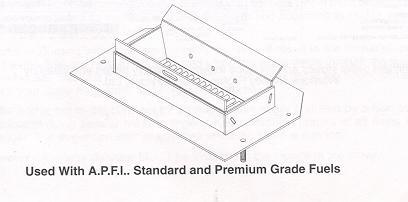

Wood pellets manufactured to the Association of Pellet Fuel Industries (A.P.F.I..) Certification Standard

are available in two grades, "Standard" and "Premium". The primary difference between the two is the ash

content of the pellets ("premium" has 1% or less ash content) ("Standards" has up to 3% ash content)

The A.P.F.I., specification for "Standard Grade" residential pellet fuel Is as

follows:

HEAT CONTENT: 8200 BTU/lb. minimum

BULK DENSITY: 40 Ib./ cu. ft. minimum

MOISTURE CONTENT: 8% maximum

ASH CONTENT: 3% maximum size: 1/4" to 3/8"diameter, 11/2" long maximum

FINES: 0.5% maximum through a 1/8" screen

CLINKING

Silica (or sand) in the fuel, along with other impurities, can cause clinkering. A clinker is a hard mass of

silica formed in the burning process. Clinkering is a function of the fuel, (not the stove), but adversely

affects the performance of the stove by blocking off the air holes in the grate. Even an A.P.F.I.. approved

pellet fuel may tend to clinker. A clinker can be removed from the burn grate and placed in the ash pan

with the use of the grate scraper / ash pan tool. See Routine Maintenance for more information on

cleaning.

ASH

The frequency of removal of the ash and maintenance performed on the stove is directly proportional to

the ash content of the fuel. A stove burning fuel with .25% ash content may only need to be cleaned out

once every 1 to 2 weeks. However, a stove burning a fuel with 3% ash content may need cleaning every 1

to 2 days.

PLEASE NOTE: Pyro Industries, Inc., has no control over the manufacturing of pellet fuel and will not be

held responsible for poor stove performance or any damage caused by inferior pellet fuels.

FUEL FEED RATES

Different brands of pellets will feed at varying rates due to their size and density. This may require a

slight adjustment from the factory setting by adjusting the damper rod "in" or "out" as needed.

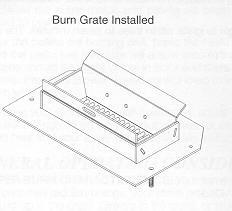

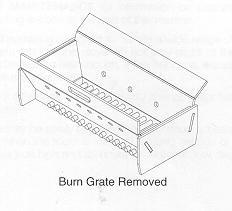

GRATE CONFIGURATION:

|

|

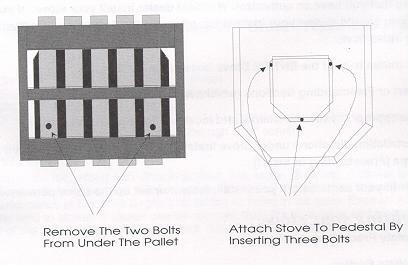

PRE INSTALLATION ASSEMBLY 1. After removing the packaging from the stove, lift the hopper lid, and remove all pre-packaged items

from the hopper. Also open the combustion chamber door and remove all pre-packaged items.

|

|

|

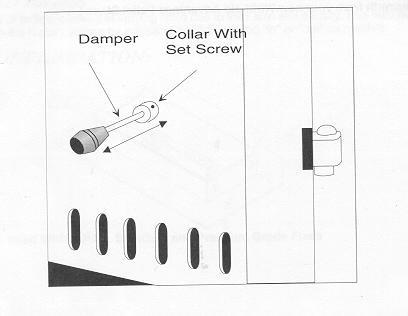

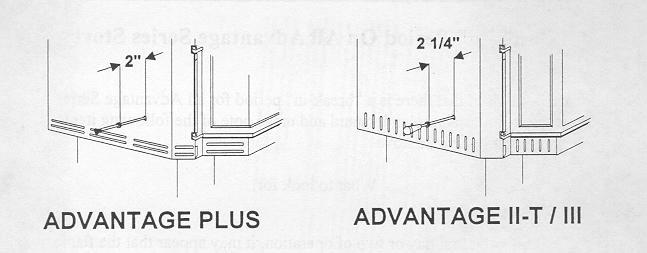

DAMPER ROD ASSEMBLY Remove the damper rod, handle and set collar from the box. Insert one end into the hole on the left side of the stove. Thread the rod into the press nut on the damper paddle. (You won't be able to see this nut.) The Damper Rod is preset at 2 1/4". Pull the rod to its fully extended position and measure from the side of the stove to the inside of the collar. If this distance is not 2 1/4", move the collar as needed and retighten the set screw with an Allen wrench. Push the rod in until the collar rests against the side of the stove. |

INSTALLING YOUR FREESTANDING PELLET

STOVE

STANDARD HORIZONTAL EXHAUST INSTALLATION

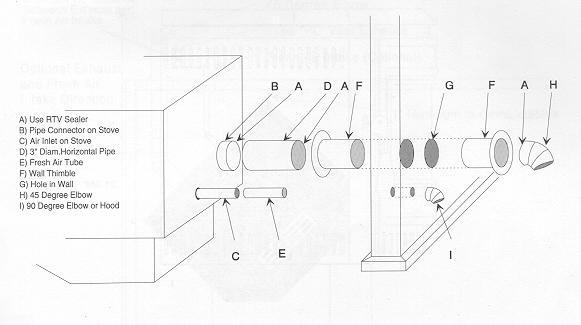

1. Locate proper position for the type "L" wall thimble (F). Use a saber saw or key hole saw to cut the

proper diameter hole through the wall to accommodate the wall thimble. (G) Install the wall thimble in the

hole.

2. Position the stove approximately 12" from the wall on the floor pad. Push type "L" pipe (D) through wall

thimble (F). Squeeze a bead of high temperature silicone (RTV) sealer (A) around the end of the

machined portion of the 3" pipe connector on the back of the stove (B). Firmly push on a section of type

"L" pipe (D) until inner pipe liner pushes into the bead of RTV sealer.

3. Push the stove (with pipe attached) towards wall. Pipe (D) will go through the wall thimble (F). Position

stove no closer than 1 " to the wall.

4. Install type "L" 45 degree elbow (H) with rodent screen cap (optional) on outside end of pipe. NOTE:

The end of the exhaust pipe must extend a minimum of 12" from the outside of the building. Rodent

screen should not be less than 3/8" in mesh.

5. If installing with combustion air from outside; cut a separate hole through the wall for the fresh air tube

(E). This tube must be 1 5/8" (min.) diameter, steel only. Connect outside air pipe to air inlet on stove (C).

This tube must be terminated with a 90 degree elbow or hood. Air may also be drawn from the crawl

space under the home.

THERMOSTAT INSTALLATION

NOTE:

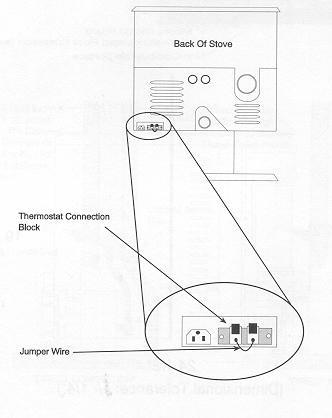

ALWAYS DISCONNECT POWER BEFORE PERFORMING THE THERMOSTAT INSTALLATION.

To Install A Wall Thermostat:

|

|

1. Check the type of thermostat you are about to install, Solid State thermostats are NOT approved for use with the Advantage Series pellet stoves. Consult your authorized Whit field Dealer for more details 2. Unplug your stove from the wall outlet 3. Locate the thermostat connection block on the back of the stove. 4. Remove the jumper wire from the "jacks" on the connection block. 5. Insert the two wires from your thermostat into the jacks (one per jack). 6. Plug in the stove and you are ready to operate with your thermostat! |

NOTE: If the jumper wire is missing, and you do not have a thermostat installed,

your stove will operate on Heat Output position # 1 all the time and at all settings.

STOVE OPERATING

CONTROLS

|

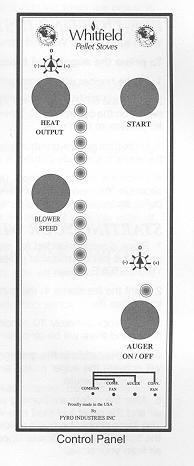

· Start Switch - The push button start switch activates the

convection and the combustion blowers. If the exhaust

temperature does not reach operating temperature within 30

minutes, the stove will automatically shut down. The blowers can

be restarted by pushing the START SWITCH again.

· Auger On/Off Switch - The Auger On/Off switch activates the fuel

feed (auger) motor only. The light located just above the switch

will blink when the auger is turning. The Start switch has to be

activated to give power to the Auger On/Off switch. When the

Auger On/Off switch is pressed a second time, the fuel feed will

stop and the blowers will continue to operate until the stove has

cooled sufficiently.

· Heat Output Switch - When not using the optional thermostat, the

Heat Output switch provides the ability to burn at separate five

settings. The Heat Output switch regulates the fuel feed setting

and the combustion air supply simultaneously.

· Blower Speed Switch - The Blower Speed switch controls the speed of the convection fan. Pressing this switch will increase or decrease the amount of heat exiting the stove. THE BLOWER SPEED MUST BE AT THE MAXIMUM #5 SETTING WHEN THE HEAT OUTPUT SWITCH IS ON THE #5 POSITION.

|

· Damper Control - The "push/pull" rod located on the lower left-hand side of the stove will NOT need to be manually adjusted

every time you turn the fuel feed rate up or down. However, the

damper allows the air-to-fuel-ratio to be "fine tuned". The proper

air setting will vary from stove to stove depending on installation

configuration, altitude and type of fuels being burned. If the flame

is a smoky red/orange with evidence of soot at the top, pull the

damper out until the flame begins to "dance". If the flame is short

at the higher heat output settings, or the fire goes out on the #1

setting, loosen the set collar and push the damper approximately

1/4" in towards the stove. Lock the set color in place against the

side panel of the stove.

NOTE: If the proper flame cannot be achieved with the damper

control, adjustment of the trim controls may be necessary.

· Combustion Fan Trim - The Combustion Fan Trim is located just

above the Heat Output Selector switch. Turning the Trim Control

counter clockwise will decrease the amount of combustion air

entering the burn grate. Turning the control clockwise will

increase the amount of combustion air entering the burn grate.

The Trim Control is factory set at the (0) position.

· Auger Trim Control - The Auger Trim Control is located just

above the Auger On/Off switch. Turning the Trim Control counter

clockwise will decrease the amount of fuel delivered to the burn

grate. Turning the control clockwise will increase the amount of

fuel delivered to the burn grate. The trim control is factory set at

the (0) position.

Web Master: There is a new digital (no dials) control panel if yours dies.

These trim controls should be adjusted as a last resort. Always

adjust the damper control first.

OPERATING INSTRUCTIONS

PRE-LIGHTING INSTRUCTIONS

When lighting your Whitfield Stove for the first time, the auger feed tube must be primed with pellets.

To prime the auger feed tube:

1. Fill the hopper with recommended pellet fuel and plug the stove into the wall outlet.

2. Press the START switch on the control panel. This will activate both blowers. Press the Auger ON/OFF

switch on the control panel. This will activate the auger motor. Next, press the heat output switch to

position #5 (maximum feed rate).

3. Look through the combustion chamber door and when you see the first pellets dropping into the grate

the auger is then fully primed. It will take 10 to 15 minutes to prime the auger.

4. Once the auger is primed, unplug the stove to turn off the blowers and auger for a minimum of 30

seconds. You need only do this when priming the auger. Once the stove is shut down, plug it into the wall

outlet again.

STARTING YOUR WHITFIELD PELLET STOVE

1. Place a recommended fire starter (see your dealer for appropriate fire starter in your area) in the burn

grate and put a handful of pellets on top of the starter. DO NOT USE FLAMMABLE LIQUIDS TO START

YOUR STOVE.

2. Light the fire starter in the grate with a match and close the door. Press the heat output selector switch

to position 3.

3. After approximately 10 seconds, press the START SWITCH. You will notice that the fire will become

active and there will be air coming from the heat exchanger tubes.

4. After the pellets in the grate are burning sufficiently (red hot coals), press the Auger ON/OFF switch:

this will activate the auger motor. and pellets will begin to feed into the burn grate. Your blower motors will

continue to operate.

5. After the pellets are burning well, press the HEAT OUTPUT selector to the desired setting. Combustion

air and the pellet fuel feed rate will adjust automatically as the HEAT OUTPUT selector switch is pressed.

The flame should be bright yellow in color and there should be no evidence of soot formation at the top of

the flame. Press the Blower Speed control knob to increase or decrease the desired amount of convection

air from your stove.

If operating your stove with a wall thermostat, adjust the heat output selector switch to the desired

demand mode (#2 through #5 on the heat output selector switch). Next, adjust the wall mounted

thermostat to the desired heat and your stove will automatically switch itself between a demand mode

and a pilot mode.

GENERAL OPERATING CONSIDERATIONS

PROPER BURN CHARACTERISTICS: Your flame should be bright yellow under normal operation. If

your flame becomes reddish/orange, your stove probably needs routine maintenance. Excessive amounts

of fly ash build-up in the grate, clinkers in the grate, or leakage of air if the grate is not properly seated will

starve the fire for air. (See ROUTINE MAINTENANCE for information on cleaning the stove). If the

problem persists review the trouble-shooting section at the end of this manual.

PELLET FEED: The pellet feed system is designed to handle a wide range of pellet sizes. Different pellets

can feed at considerably different rates. If the stove will not stay alight at the minimum fuel feed setting,

those particular pellets may not be feeding fast enough. If this happens, adjust the damper rod (on the

side of the stove) in or out to achieve a proper burn.

PELLET SIZE: You may notice a difference in the burn if you change pellet fuel sizes. The bigger the

pellet, the slower it will feed and vice versa.

LONG BURN TIME: The stove may be safely operated on a continuous basis, but it is recommended that

it be turned down overnight or when the room is vacated for long periods of time. A 40 lb. bag of pellets

should last approximately 10 hours on high and 35 hours (or more) on low, depending on the type and

size of pellets you are burning.

AUTOMATlC SAFETY FEATURES

Power Outage

During a power outage, the stove will shut down safely. It will not automatically restart when the power is

restored unless the exhaust is still up to temperature. A small amount of smoke may leak from the top of

the window glass, the hopper and from the combustion air intake. This will not persist for more than 3 to 5

minutes and will not be a safety hazard.

To re-light the stove, follow the normal procedure for starting your stove.

NOTE: If you are installing this pellet stove in an area that is prone to frequent power outages, it is

recommended that there be a minimum of 3' (Feet) of vertical vent pipe included in the installation to

induce a natural draft in the event of a power failure.

Overheating

A high temperature switch will automatically shut down the stove if it overheats. The stove will need to be

manually re-lit. Allow 45 minutes before re-lighting.

TURNING OFF YOUR WHITFIELD PELLET STOVE:

Press the Auger On/Off Switch to the "OFF" position. This will turn the auger motor off and pellets will

stop feeding. Both blowers will continue to operate for a period of time (up to 45 minutes) until the

exhaust temperature cools sufficiently. The blowers will automatically turn off at that point.

LIGHTING STOVE WITH OPTIONAL FASTFIRE SELF-IGNITER

If you have purchased the optional FASTFIRE Self-igniter from your dealer, you will need to perform

the following start-up procedure:

1. Make sure the auger is primed (see Pre-Lighting Instructions above), then simply push the Start

button on the control board to activate the igniter.

2. Press the Auger On/Off Switch to the "ON" position.

3. While the pellets will ignite on any heat output setting' it is recommended that the Heat Output Knob be

set to position #3 or #4.

4. Pellets will start feeding into the grate and should begin to ignite within three to seven minutes. The

self igniter will automatically shut off after 15 minutes.

ROUTINE CLEANING

NOTE: STOVE WILL NEED TO BE SHUT OFF AND COOLED ENOUGH TO

HANDLE BEFORE ROUTINE CLEANING IS PERFORMED.

ALWAYS DISCONNECT POWER BEFORE

DOING ANY ROUTINE CLEANING.

The amount of fly ash bulid-up in your stove is directly proportional to the ash content of the fuel that you

are using (see PELLETS, page 6). After a period of time (a week, or so) inspect the heat exchanger

tubes, the burn grate, and the ash traps behind the fire brick. You will want to gauge your routine

maintenance accordingly.

THE FOLLOWING AREAS NEED TO BE INSPECTED DURING ROUTINE CLEANING:

· Burn Grate . Heat Exchanger Tubes

· Ash Pan

· Ash Traps and Baffles

Burn Grate: The bum grate should be inspected periodically to assure that the air holes have not become clogged with ash or clinkers. The burn grate can easily be cleaned with the grate scraper/ash pan tool, or it can be removed for cleaning. It is very important to monitor the ash build up under the burn grate, as excessive build up may starve the fire of combustion air. When burning "Standard" grade pellets, it will be necessary to clean the ash pan more often than when burning "Premium" grade pellets.

|

|

|

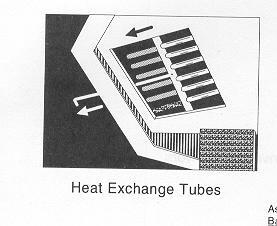

Heat Exchanger Tubes: located above the combustion chamber door is used for cleaning the

tubes. By pulling this rod in and out a few times, you will clean the fly ash off the heat exchanger

tubes. If your stove was recently turned off, the rod may still be hot. Handy Hint: you may want

to wrap a damp cloth around the rod when you clean the tubes. This will prevent fly ash from

being drawn into your house from the pulling action of the rod.

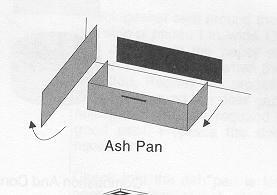

Ash Pan: The ash pan will have to be emptied whenever necessary. First, remove the ash pan trim

piece located below the door. Grasp the knob located on the ash pan door and swing the door

open. Then, using the ash pan/grate scraper tool, lift the grate out and sweep the top ash into the

pan, below. Then, remove the ash pan with the tool. Be sure to gently dump the ashes into a non-combustible container. When finished, slide the ash pan back into the stove and close the ash pan

door and replace the ash pan trim piece.

Cleaning of Ash Trap Baffles: Access to the ash trap baffles (behind the two side firebricks) is

obtained by loosening the screws that hold the "Brick Retention Plates" in place and lifting the

clips away from the stove. After the clips have been removed, remove each side brick first, then

the center firebrick. Thoroughly clean out areas where ash has collected behind the firebrick. The

amount of time between cleanings will be directly related to the ash content of the pellet fuel being

burned. Excessive ash build up in the baffle area behind the brick panels will restrict the exhaust

passages and cause less combustion air to enter the firebox and which can lead to poor

performance and a "dirty burn".

Handy Hint: After the first 10-20 bags of fuel, you may want to remove the firebrick and

determine the rate at which the fly ash is building build up within the stove. Contact your dealer

for more information should you have any questions regarding this procedure..

|

|

|

|

|

ROUTINE MAINTENANCE

The following areas need to be inspected as part of routine maintenance:

Door Rope Gasket: The condition of the rope gasket around the door and windows should be checked

periodically and replaced or repaired if necessary.

Exhaust Vent: Inspect frequently and clean when necessary. Fly ash will accumulate at all bends in the

exhaust system. Large amounts of fly ash will starve the fire for air.

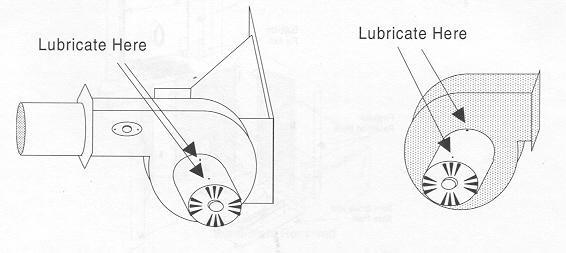

Motor Lubrication: The two blower motors require lubrication annually with not more than two drops of

high temperature turbine oil (available from your dealer) at the lubrication points shown below.

Trouble Shooting

| Page 1 | Page 2 | Page 3 |

ADVANTAGE PLUS ADVANTAGE II-T / III

When your new stove is installed; the exhaust should hooked up, the stove

plugged in and the fire started. Check for proper operation at all heat output

settings (#1 - #5). Look for a brisk yellow flame with no black tips.

Any adjustments for combustion air should be made at the damper by varying

the spacing between the side of the stove and the inside of the damper set

collar. The factory setting on the damper, as noted above, should correspond

with the model you have.

If the fire goes out on the #1 setting, you will want to decrease the

combustion air flow. Loosen the set collar and push the damper in by 1/4"

intervals. Tighten the collar at its new position (2 1/2" - 2 3/4").

If the fuel is building up in the bum grate at the higher heat output settings,

you will want to increase the amount of available combustion air. Loosen the set

collar on the damper rod and pull the damper out. Do this 1/4" at a time. Tighten

the collar at its new position (1 3/4" - 2").

After making any adjustment to the damper set collar, pull the damper rod out

fully and re-check the dimension between the stove side panel and the inside if

the set collar.

Should you find that the fire is still not burning properly, contact your authorized

Whitfield Dealer for assistance.

Part No. 60020008

Technical Bulletin

PLEASE READ BEFORE LIGHTING STOVE!

"Break-in" Period On All Advantage Series Stoves

Please be advised that there is a "break-in'5 period for all Advantage Series Stoves. It is

important to understand and make note of the following items when you first light your

stove.

What to look for:

· During the first day or two of operation, it may appear that the flame

pattern is somewhat short and vigorous. This is due to the "break-in" period of the auger motor.

·

During this period, the auger motor will gradually speed up it's rotation cycle as the gear

box wears in. This will correspondingly increase the fuel feed rate. The flame pattern will

grow accordingly, and the damper rod may need to be pulled out slightly to compensate.

·

DO NOT ADJUST THE CONTROL BOARD'S INTERNAL SETTINGS AT THE

TIME OF INSTALLATION! All adjustments to compensate for burn characteristics

should be done with the damper on the left hand side of the stove by moving it in or out

slightly a quarter of an inch at a time. Please see your Owner's Manual or your Operation

& Maintenance Video for more information about damper adjustments.